Design the Braze Joint to have proper clearance at braze temperature

Thermal expansion when brazing is about the material property of a volume change in response to changes in temperature. The net volume growth over a given temperature is dependant on the initial volume of the component. Therefore, for most common braze materials (copper, stainless steel, ceramics to metal, aluminum, etc), this expansion varies.

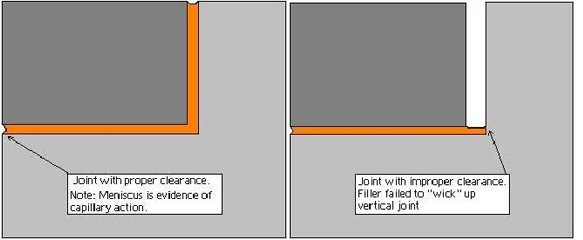

Usually, it varies from four to twenty-thousandths of an inch of growth per inch of material in a given direction. With this in mind, brazed assemblies with different materials must be designed and toleranced such that the joint has the proper clearance at braze temperature. Without the proper clearance, the filler may not wick and produce an unhealthy braze joint. The considerations must also take into account the thermal expansion of each individual material and it’s unique thermal properties.

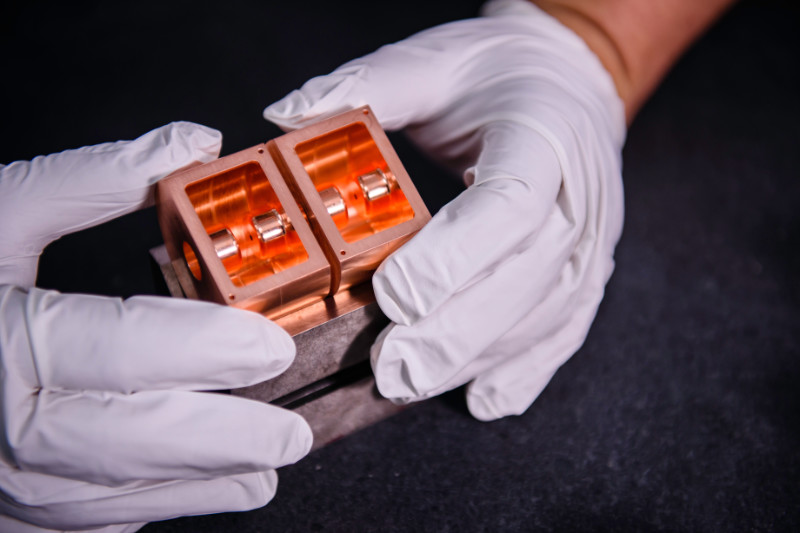

On the surface, brazing may seem like a simple process. Although some aspects are fundamental, the reality is that as materials and configurations become more complex, so does the underlying process. This is where Altair’s expertise in joint design, experience with fixturing, and precise process controls make the difference between a successful braze and scrap metal.

To achieve proper clearance, braze joint fit-up at room temperature may need “excessive” clearance or even “interference” such that at braze temperature, proper joint clearance exists to allow capillary action to work.

Fixturing is an essential tool to manage thermal expansion

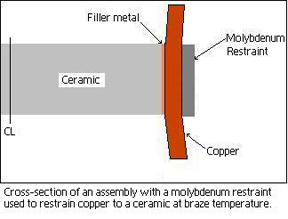

When dealing with materials with vastly different coefficients of thermal expansion (CTE) (brazing copper or stainless steel to ceramic, for instance) fixturing becomes essential in creating the correct joint clearance. Fixtures work by using thermal expansion relative to one part in order to “re-size” (plastically deform) it to create the proper clearance between its mating part at temperature. What usually determines the type of fixturing needed (restraint vs. pusher) is the component that is the easiest to deform at braze temperature and its position relative to the stronger component. A combination of yield strength and geometry will determine the ease of deformation. Fixture material must have higher yield strength at temperature than the deforming material in order to address thermal expansion when brazing. Therefore, we use molybdenum and other refractory metals for fixturing due to their high strength at high-temperature profiles.

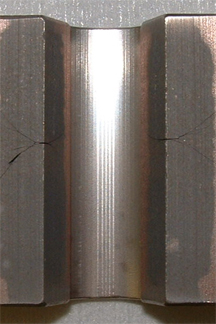

After brazing is complete and during cooling, stress will creep into assemblies from differential shrinkage. The greater the CTE difference, the greater the stresses will be in the final assembly. Be mindful of joint location relative to geometry as joints can see multiple shear tension, and/or compressive forces acting towards stress concentrations. When dealing with ceramics, it is especially important to design joints as to not create tension and shear stresses since cracking the ceramic or de-lamination of metallization can occur with minimal force.

Additionally, furnace process controls become increasingly important since the temperature ramp rate is ultimately what controls the instantaneous differential expansion between components that heat differently.

We have years of experience bonding dissimilar materials with varying coefficients of thermal expansion. Our next blog entry will detail a sample CTE calculation depicting the approach of determining the nominal room-temperature dimensions to achieve an ideal braze gap distance at b