Design Guidelines for Vacuum Aluminum Brazing

Many of our customers include machine shops who prefer to consign aluminum components to us for vacuum brazing aluminum often miss key aspects of braze-joint design. In order to provide a high quality braze joint, it is very important the components are properly prepared for excellent capillary action (Wetting).

We can’t emphasize this enough and all too often inexperienced customers compare vacuum aluminum brazing to torch brazing or dip brazing, having little concern for the machining of parts to be brazed. For the sake of this post, we’ll assume the assembly to be brazed only has horizontal braze joints. Components made from Al-6061, Al-1100, and 3000 series Al are the most common types of Aluminum we see.

Engineering Requirements and Design Guidelines

- The mating surfaces to be vacuum aluminum brazed must be flat and less than 0.003 inches (max).

- Milled or turned surfaces with a 32 to 64 micro-inch surface finish work best. Jitterbugging with aluminum-oxide paper is NOT recommended and the use of silicon carbide is preferred; wire brush surface prep is not sufficient.

- Do not use any lapping compounds on surfaces to be brazed.

- Machining can impart redsidutal stresses into the Aluminum components, which will be released (causes warpage) during the thermal cycle of the braze run.

- There may be some warping and there will be some indentation from the local pressure points and braze blush, caused by the braze alloy (filler metal) that is being squashed out of the braze joint.

- Therefore it is imperative that the components have at least 0.050 inches of excess material to be final machined after brazing.

- The brazed assembly will be annealed and usually, we will send the assembly to be heat-treated to a T6 before final machining.

- Al-1100 cannot be heat treated.

- Aluminum forms an oxide in the air at room temperature and in order to get a high quality braze joint, the oxide must be completely removed allowing for a bond to the native metal surfaces.

- If you are a machine shop choosing to conduct business with us via consignment, your Aluminum components that are to be brazed need to be light chemically etched and then vacuum sealed or sealed in a suitable plastic bag with an inert gas prior to shipment.

- We can execute this process step for you at an additional charge.

- As you are learning, there are manhy details and challenges to the vacuum brazing of aluminum. We recommend inquiring about our full turnkey solutions that handle the entire brazing process from design to testing, hence lowering overall risk for you.

- If you are a machine shop choosing to conduct business with us via consignment, your Aluminum components that are to be brazed need to be light chemically etched and then vacuum sealed or sealed in a suitable plastic bag with an inert gas prior to shipment.

- Braze runs usually take > 5 hours from start to finish.

- In order to accurately measure the temperature of the assembly being brazed, we highly recommend placing a 0.075 inch diameter thermocouple hole on one of the outer vertical surfaces.

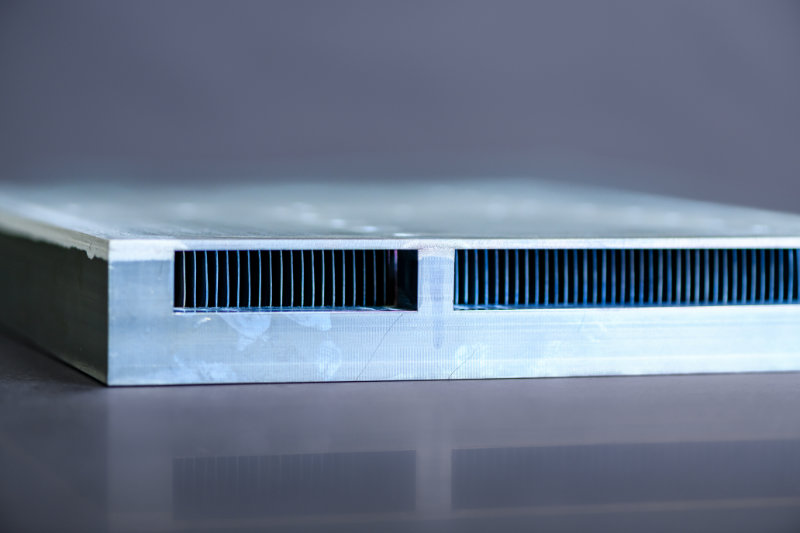

- If your design has a cooling channel, make sure there is a vent hole (larger the better) that will allow the vacuum furnace to pull a vacuum on the channel once the parts are assembled for brazing.

- In cases where you have a disk-shaped component dropping into a C’Bore, the vent hole keeps air from being trapped, making it very difficult to get the mating surfaces in intimate contact. These vent holes are also needed for heat treating.

- The surfaces to be brazed must-see adequate pressure in order to braze properly.

- The braze filler or alloy contains a little Silicon (Si), which lowers its melting temperature below that of the parent aluminum materials. During the braze run and in the hot zone, some Si will vaporize into the vacuum atmosphere and some will diffuse into the parent material, leaving a small transition zone on either side of the braze joint.

- The resulting braze joint is very thin and almost identical in composition to the mating aluminum components.

- Brazing aluminum to other types of refractory metals can be tricky due to the brittle intermetallic. Some metals like Titanium braze well with aluminum, however, if you need to braze Copper to aluminum, it’ll require our innovative, proprietary process.

Depending on your design, the requirements and guidelines above may be more than adequate to help us give you high quality brazed assemblies; it is always a good idea to have our engineers review your drawings. Contact one of our specialists today for a quick feasibility study of your project.