Project Summary

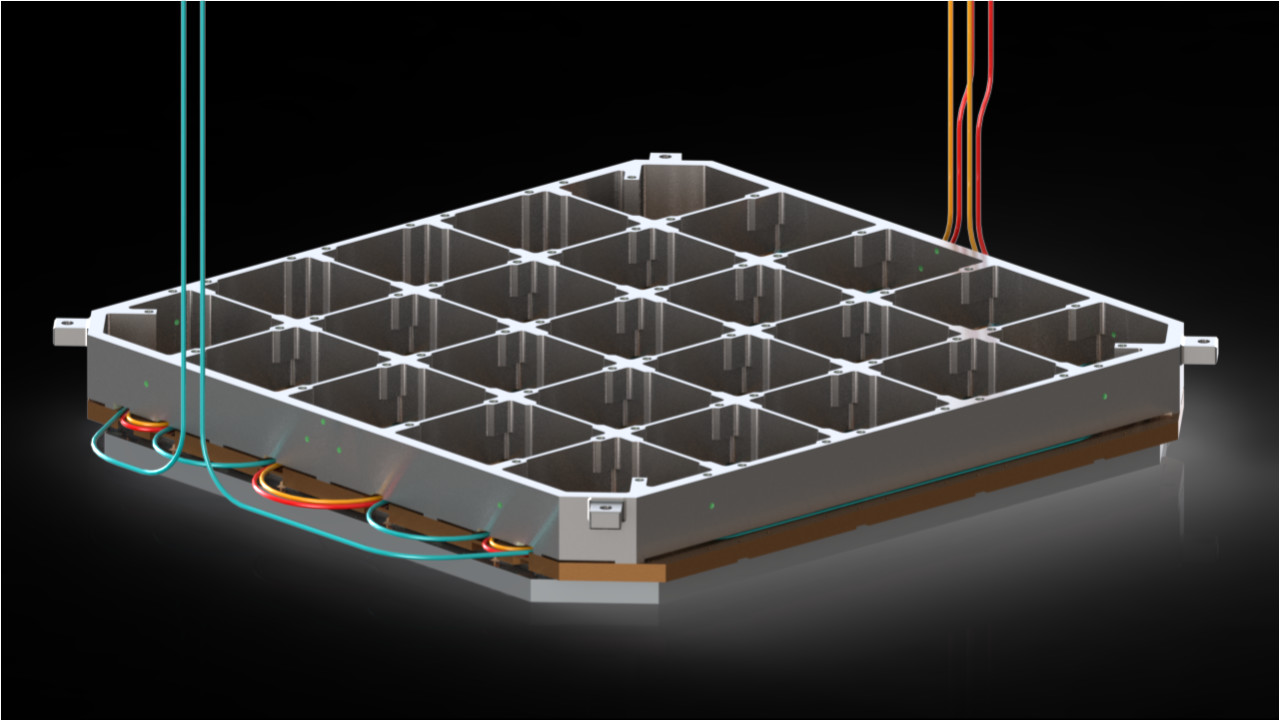

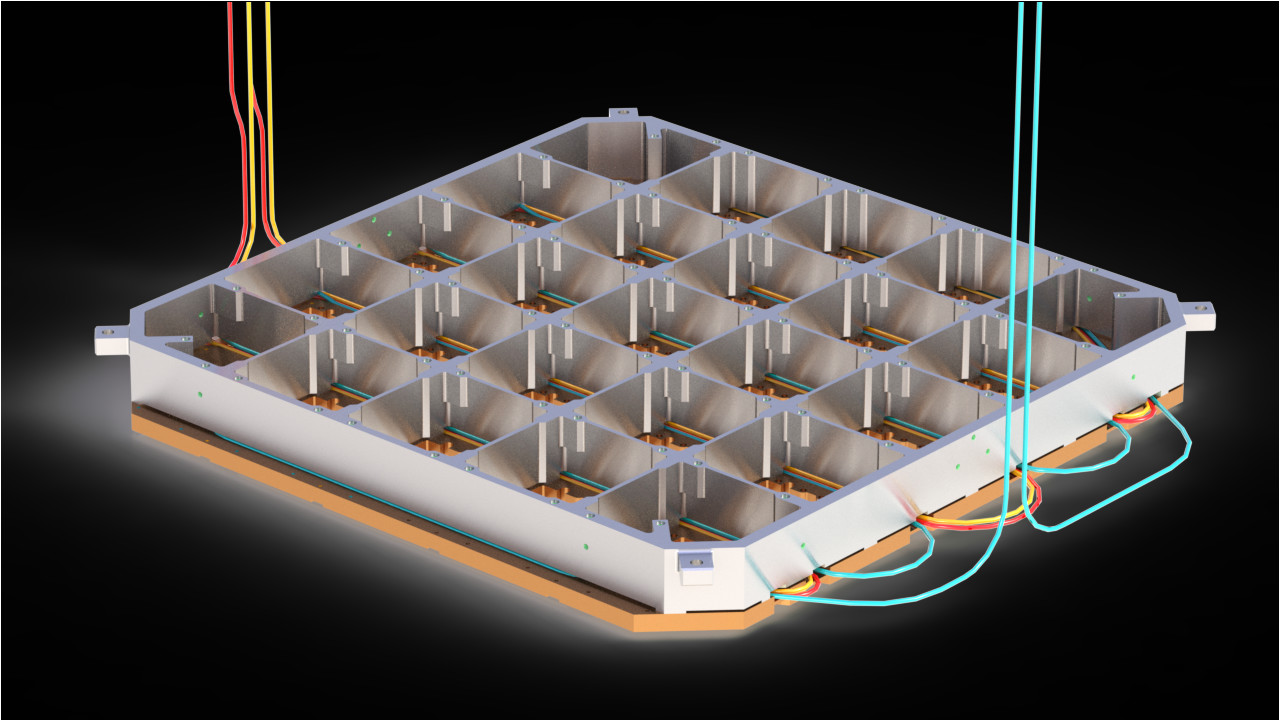

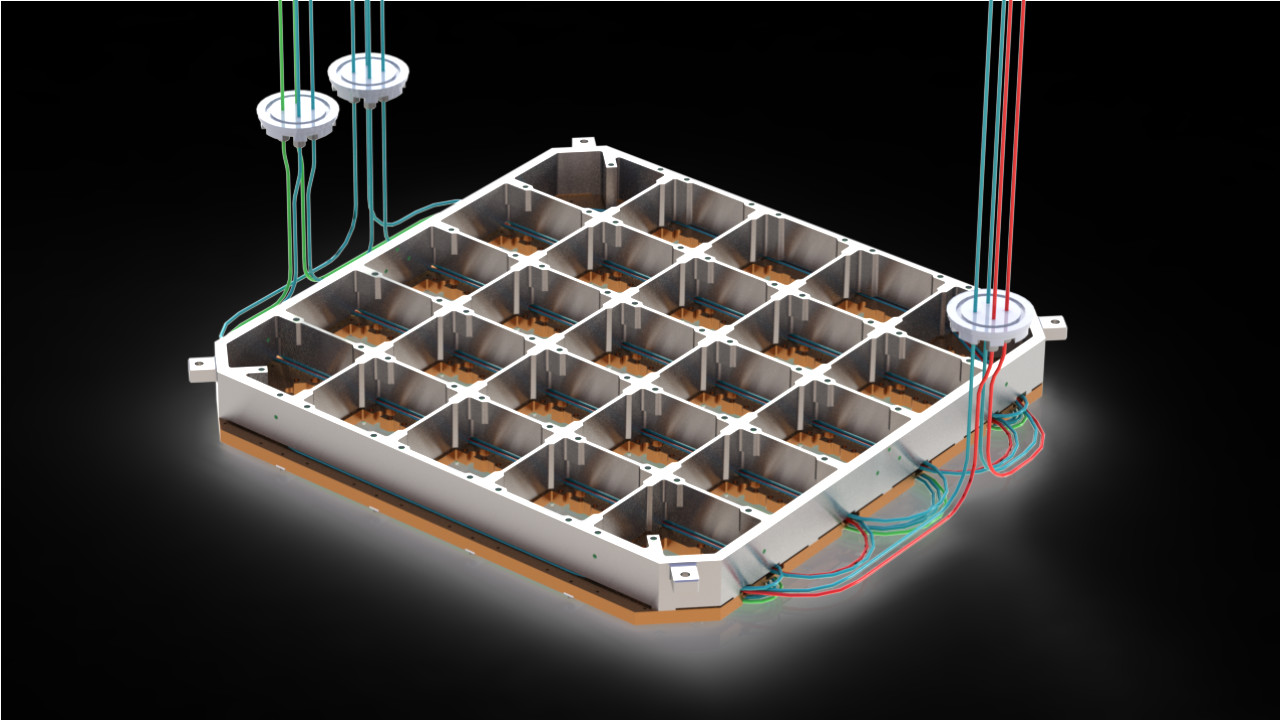

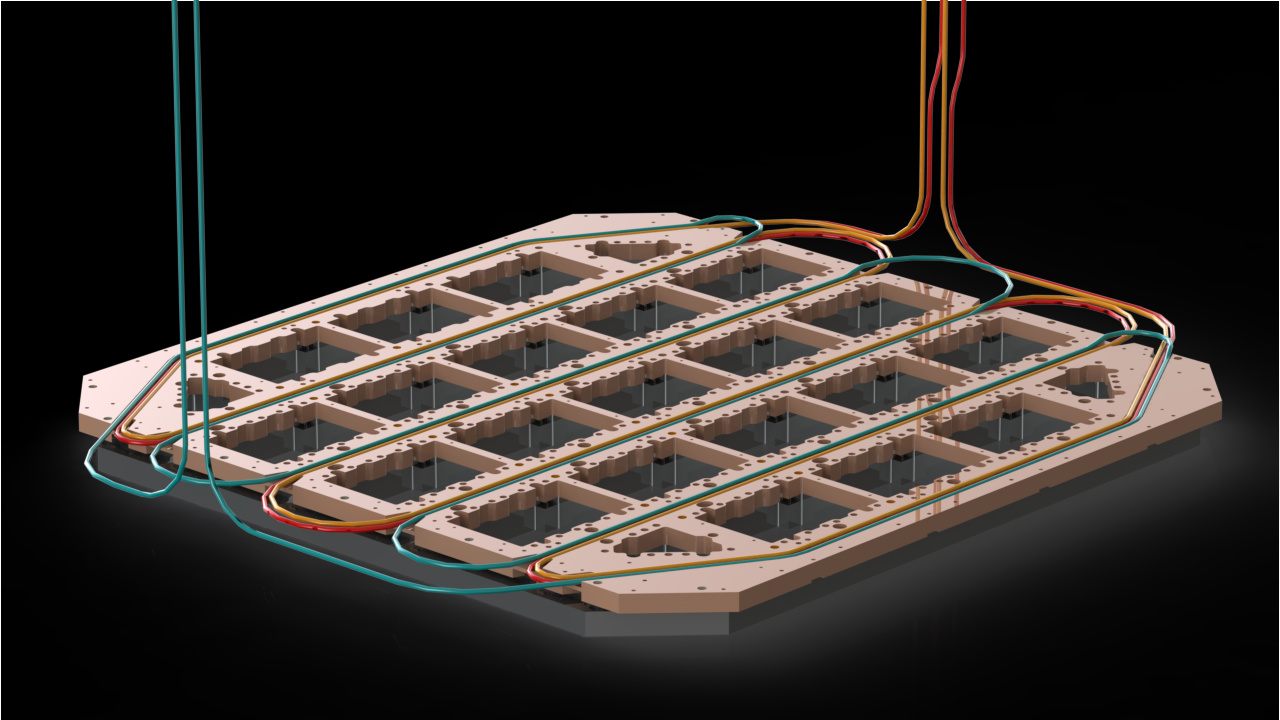

The Cryostat Cryoplate was the first of its kind to ever be developed. This is because it was developed for the largest digital camera ever built, The Large Synoptic Survey Telescope (LSST). We took the engineering and design of the Cryoplate from the early stage 3D CAD models the customer provided all the way to the final product. Our complete turnkey solution did not just include the engineering and design of the product, we developed the entire manufacturing process and the necessary tooling/fixturing to conform and braze a 40 foot array of SST tubing to a 27 inch x 27 inch copper plate.

-

Start Date 03/27/2018

-

Customer: SLAC

-

Product: ARG & Brazing Services

-

Altair Engineer: Adam Mitchell

The Challenge & Solution

The challenge was designing fixturing that would deliver the force required to conform the SST tubing to the Cu plate, making up for the inherent lack of precision with bent tubing. The development of the fixturing system to conform the SST tubes to the Copper plate was crucial to the success of the LSST Cryoplate project. The project was a long and very involved project that required a good working relationship between the Altair and SLAC teams over the course of 8 months. During the project, custom tools and precision furnace profiles were developed to meet the customer’s requirements.