History & Milestones

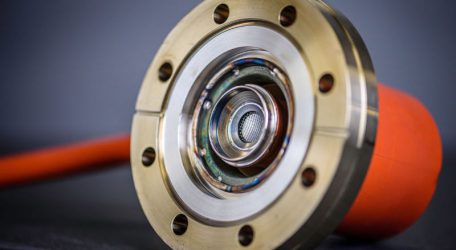

1995 - Altair's S-Band RF Window

In the mid 90’s, Altair introduced its first-ever proprietary products, an S-Band RF Window designed for medical oncology accelerators. Today we sell hundreds of these RF Windows and have leveraged this original design into many new RF Windows for various applications.

1997 - In-House CNC Machining

In-house machining capability was actualized with 5 CNC's and a complement of manual machines.

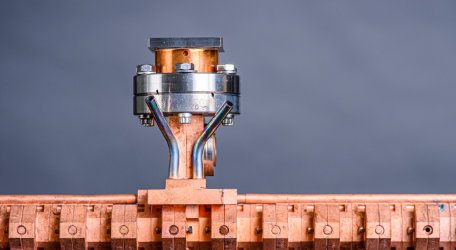

2003 - Turnkey Brazing for OEMS

In 2003, Altair developed an all-brazed Degas Pedestal for a semiconductor capital equipment OEM, and soon thereafter, we replaced their existing supplier and began supplying this high-level assembly in Tier 1 fashion.

2003 - Vacuum Components for Oncology

Also in 2003, Altair developed and later qualified its very first Electron Gun and 2 Liter Ion Pump products targeted at medical accelerators used for oncology treatments.

2004 - Defense Radar systems

By 2004, Altair completed an extensive product transfer with a local defense contractor and began supplying millions of dollars worth of high-level assembly products for a Navy shipboard radar system.

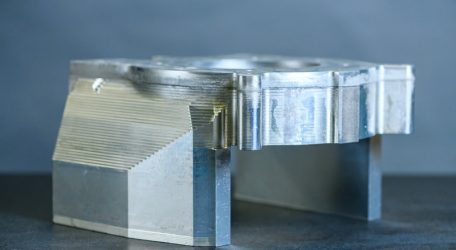

2007 - S-Band Medical LINAC

In 2007, Altair submitted a patent application for an improved and novel fixturing design used primarily on vacuum brazed aluminum assemblies. Altair also developed many specialized in-house processes, component sub-assemblies and tooling to remanufacture its first-ever S-Band Medical Accelerator. Altair set a new in-house record for producing 20,000+ Electrode assemblies per month on a recurring basis becoming not only a high-mix low-volume producer, but a high-volume production house as well.

2007 - Bakeout for High Vacuum Components

In 2007, bakeout capability for high vacuum components was added to better serve the electron beam and ion device community with pre-processing steps for high vacuum applications.

• 6 Independent Cryogenic Ports

• Two Independent Bells

• Automated Controls

• Ultra High Vacuum

• Efficient Device Conditioning

• Flexible Configuration

• RGA Measurements

2007 - Oversized Assembly Capabilities

In 2007, purchased large vertical furnaces with separate heat zones to accommodate oversized assemblies for hydrogen and vacuum brazing.

• 2 PVT Vacuum Furnaces

• 28” x 28” x 28” Hot Zone

• 42” x 28” x 28” Hot Zone

• Temperature Profile Recording

2008 - LINAC for Oncology OEM

In 2008, Altair perfected a process and mechanical design to eliminate the spring-back effect that occurs on Moly grids after forming and etching. Altair collaborated with a large oncology OEM to facilitate the manufacture of a next-generation Accelerator, successfully building several guides to specification.

2008 - 100% yield for 2700 Assemblies

From 2008 – 2010, Altair brazed >2,700 consecutive ESC Aluminum Cooling Assemblies with zero defects (100% first-pass yield!)

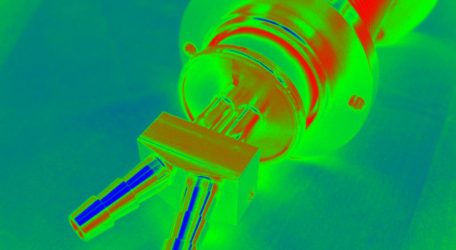

2009 - Suite of Engineering Software

In 2009, Introduced a complete suite of en gingering analytical simulation software, including FEA, CFD and RF/Particle Optics.

2009 - Targets for Oncology

In 2009, Altair developed and shipped a high energy Target Assembly compatible with several thousand oncology machines/accelerators worldwide.

2012 - X-Band Mobetron

In the summer of 2012, Altair shipped its first turnkey X-Band Mobetron accelerator. The guide is targeted for the medical market specializing in electron therapy. Altair Engineering implemented various redesign features and contributed to the development of new IP, WSBK, SSBK, Novel electron gun for extreme back-heating, Novel energy switch, Altair designed multi-energy electron accelerator 6,9,& 12 MeV, Altair shipped 6 MeV S-Band, Multi energy, multi radiation guide 6-15 MeV

2018 - The Altair Research Group

In 2018, Altair formed, "The Altair Research Group" (ARG). The group provides an industry-leading competency within Altair for designing, improving and trouble shooting high-vacuum microwave electron devices; members have over 30 years of experience in the field.

2019 - Turnkey Brazing Aluminum

In 2019, Altair developed a new process/service for full-turnkey brazed aluminum products that lowers overall cost and lead time while maintaining Altair's top quality requirements.