Altair was born from the Medical Industry

Altair was conceived from Varian engineers who had the vision to start a company that would braze Varian’s LINACs together because, in the ’90s, Varian desired to outsource manufacturing while focusing on their own efficiencies. Although Varian ultimately did not outsource their brazing, the Altair founders set up shop with a single brazing furnace and designed their first RF Window Assembly.

The worldwide healthcare market is influenced by technology that is addressing an ever-increasing number of medical ailments and is aiding in early diagnosis and prevention of diseases. We support many linear accelerator products for customers who make X-Ray Tubes for CT Scanners to those for cancer radiation therapy treatment and early detection of cancer (Oncology).

Complexity & Materials

With our proprietary vacuum and hydrogen brazing process, we can join dissimilar and exotic materials with precision for a myriad of applications that would not be possible otherwise. Vacuum brazing and hydrogen brazing is a powerful manufacturing technique that engineers and scientists can leverage to circumvent many of the challenges of complex geometries, miniaturization and traditional assembly design.

Benefits of Altair's Proprietary Brazing Technology

Miniaturization via precision manufacturing without material deformation.

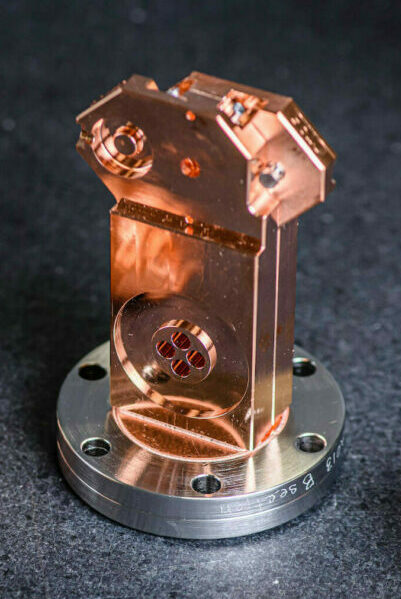

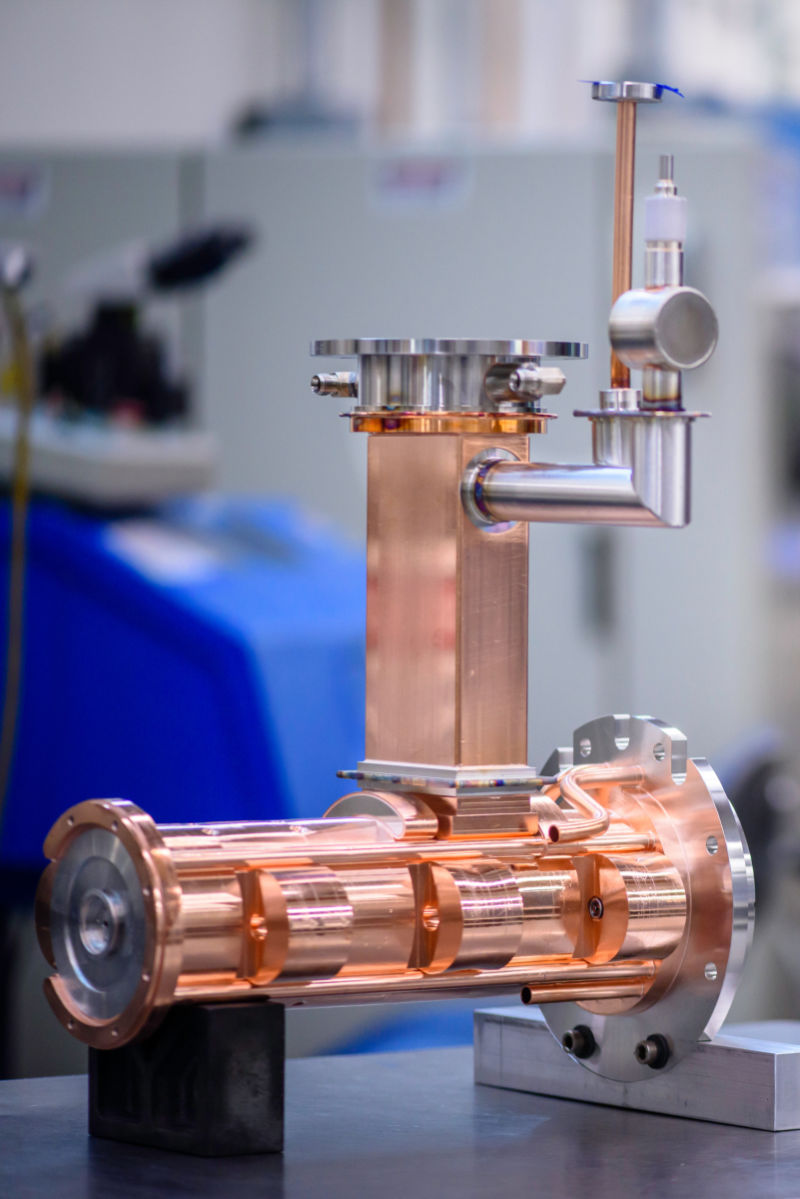

We have developed our own linear accelerators (LINACs) and many proprietary products such as RF Windows, Electron Guns, Exit Windows, Waveguides, Anode Assemblies, Target Assemblies and Ion Pumps that make up the fundamental structure of a complete LINAC used in Oncology Systems.

We support many products for customers who make X-ray Tubes for CT Scanners to those for treatment and early detection of cancer.

Altair Products can serve as a direct fit peripheral to your OEM structure, or a replacement for failed assemblies on existing systems and machines. Work or working with our channel partners to refurbish or remanufacture your OEM’s accelerators using Altair engineered and manufactured peripherals.

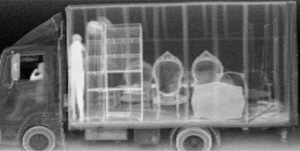

Security Industry X-Ray & Cargo Inspection

The work we do for the medical industry leverages naturally into the Security X-Ray and Cargo Inspection market, which also uses X-Ray Tubes and Linear Accelerators (LINACs). These devices produce high energy X-Rays which are used in cargo inspection systems of baggage, semi-trucks, ship hulls and other types of cargo.

For X-Ray Cargo Inspection, Dual-energy CT combines two advanced approaches into one technology where the object is scanned with two different X-ray energy spectra. It allows not only the reconstruction of 2D images of the objects in a cargo container, but can also be used to estimate the density and the effective atomic number of different objects.

Brazing vs. 3D Metal Printing

Metal 3D-Printing is one of the fastest growing sectors of the additive manufacturing industry and already disrupting the CNC machining, casting and prototyping industries. It is by the far easisest solution for younger engineers and designers because the constraints on design are reduced by an order of magnitude. We are actively investigating how we can leverage this powerful technology for our customers, however as of today, due to it’s pourosity and other challenges it cannot provide the performanve our customers demand.