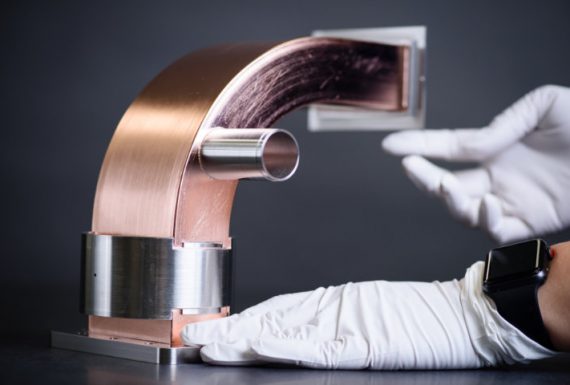

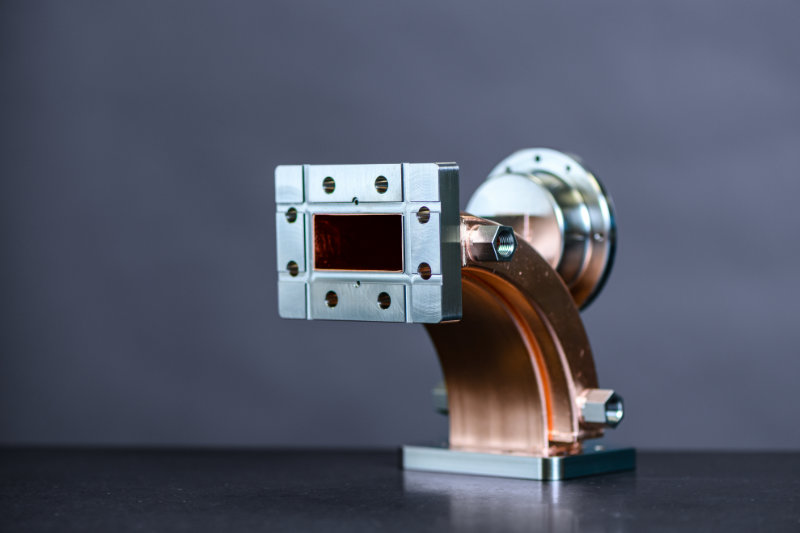

Most of the waveguides we make are used in vacuum or vacuum (one-side) and pressurized gas (the other side) applications. Most waveguides use stainless steel flanges (SLAC-type, Varian-Type, LIL, Cover, Choke and more) and extruded or machined copper guide as the transmission line. We also design and fabricate Aluminum waveguide assemblies using our vacuum aluminum brazing process.

We have the in-house testing capability and quality control to ensure our designs meet the desired low insertion loss and high transmitted power requirements (VWSR). Low loss designs can also be silver or gold plated to reduce microwave losses and ensure maximum energy propagation.

If you have a requirement for a custom waveguide assembly and need help with its design and fabrication, we can help with the engineering, the voltage or power handling, bandwidth, modes and braze and/or weld designs. In many cases, we can fabricate components in-house to ensure quality and expedited delivery.

We do not offer standard waveguide straight extrusion sections and components alone, or other preassembled configurations using materials such as aluminum and brass. If you are looking for standard waveguide components such as flanges or tube sections please visit www.pennengineering.com