Target

Assemblies

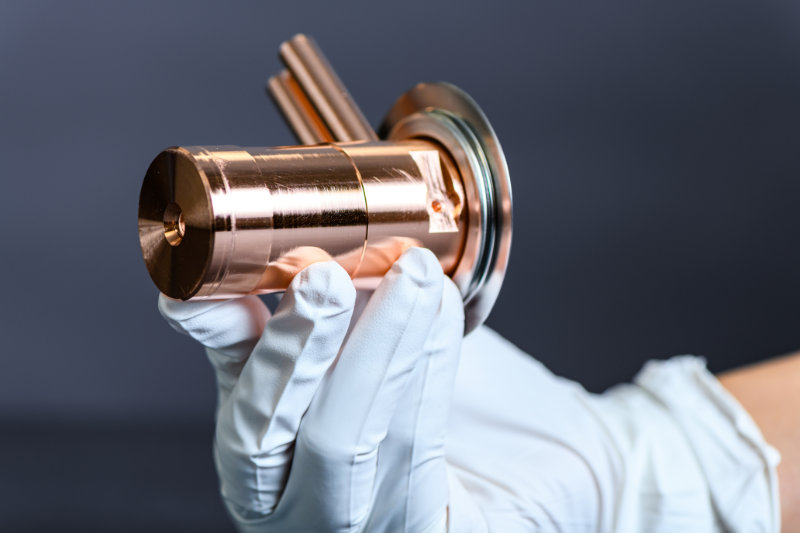

Developing tungsten, and tungsten alloy target assemblies for medical and industrial linear accelerators (LINAC), as well as X-Ray sources

In more recent years we designed and developed a family of proprietary medical target assembly products and exit windows designed specifically to mate with Siemens and TomoTherapy guides and as a drop-in replacement for Varian’s high-energy and low energy guides. Not only do we offer our own aftermarket designs, but we also remanufacture the existing OEM’s Target Assemblies. Remanufactured targets meet all the requirements of the OEM version, including life expectancy and warranty, but usually at a fraction of the cost.

Target

Assemblies

Developing tungsten, and tungsten alloy target assemblies for medical and industrial linear accelerators (LINAC), as well as X-Ray sources

X-Ray

Target

Surface

Finishing Process

Up to 4 micro-inch surface finishes

In more recent years we designed and developed a family of proprietary medical target assembly products and Exit Windows designed specifically to mate with Siemens and TomoTherapy guides and as a drop-in replacement for Varian’s high-energy and low energy guides. Not only do we offer our own aftermarket designs, but we also remanufacture the existing OEM’s Target Assemblies. Remanufactured targets meet all the requirements of the OEM version, including life expectancy and warranty, but usually at a fraction of the costs.

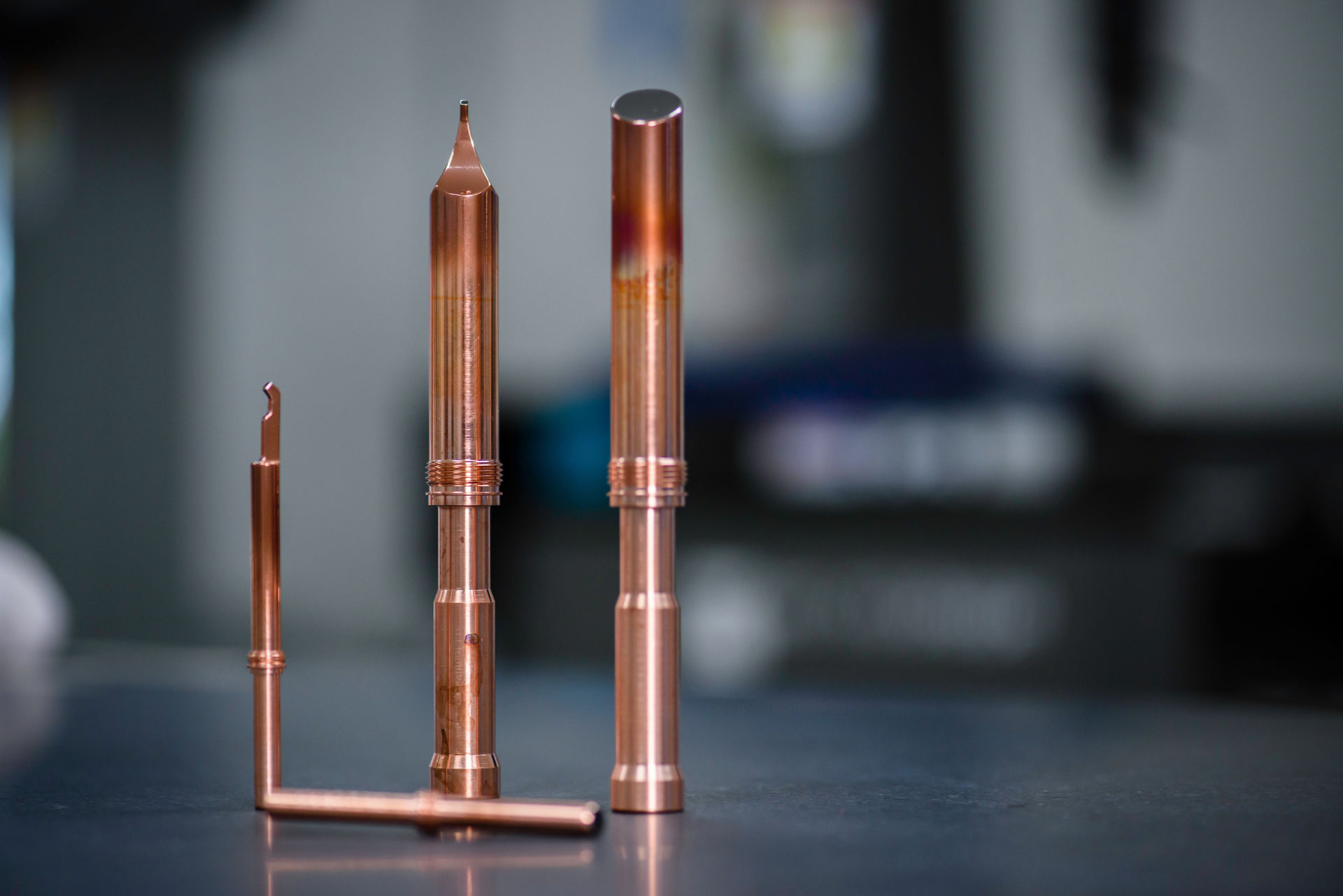

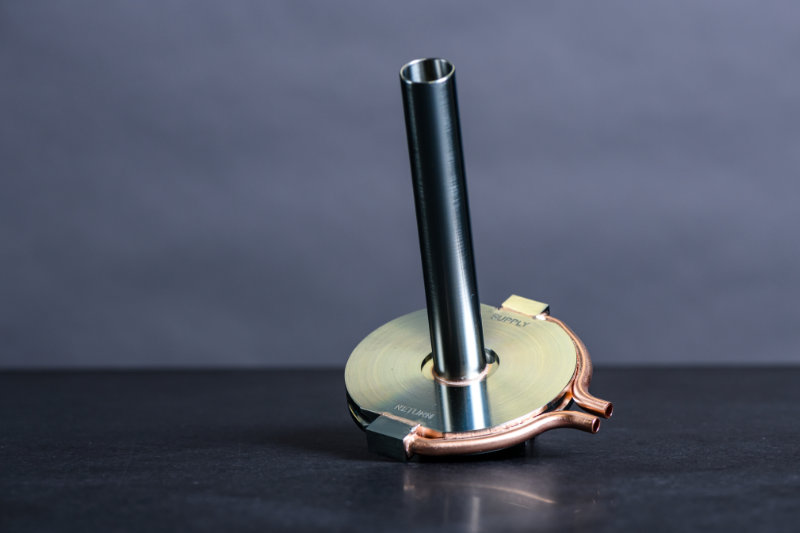

Target Assemblies are critical components of any X-ray Tube, or medical or security linear accelerator. For almost two decades and continuing today, we have been building various turnkey Target Assemblies based on our customer’s design or needs, and are also innovating new designs for optimal output conditions.

Target materials are typically Tungsten, Tungsten alloys or other suitable metals. In some cases, target surface finishes can be on the order of 2, 4 to 8 microns, which is typically achieved by lapping or polishing by hand or by a manual process.

However, when examined under magnification and incident relatively intense light, stray scratches or striations can be seen leaving a less than perfect uniform appearance, which leads to less than desired performance.

We have developed an automated process that uses no foreign matter or polishing compounds and achieves both the desired surface finish and near-perfect uniformity. At the customer’s request, Target Assemblies can be clean fired, baked-out and/or stored in vacuum-tight metal canisters.