Project Summary

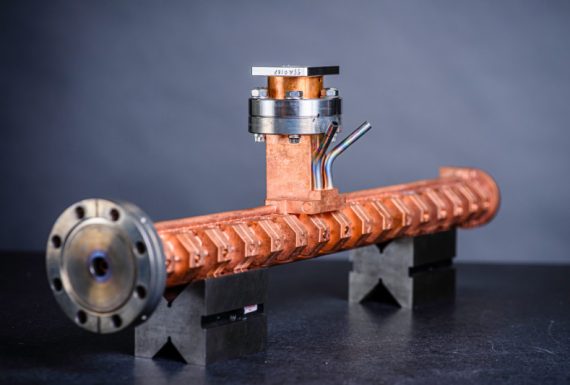

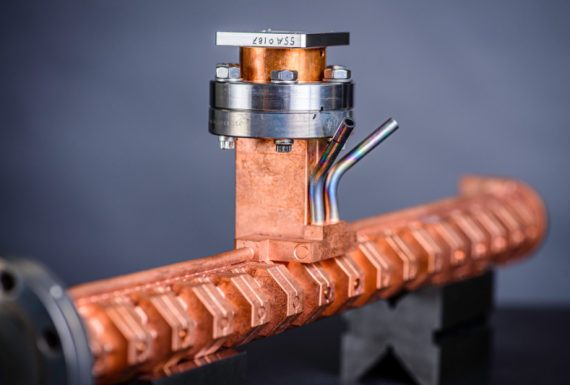

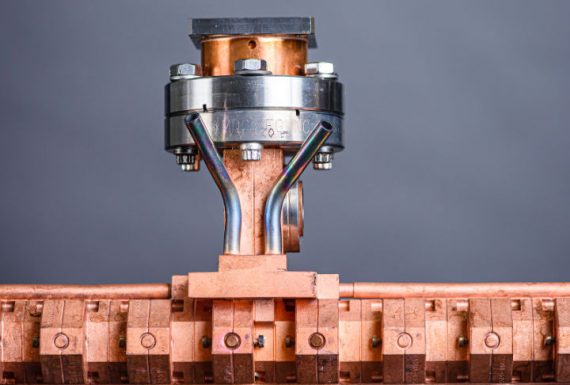

An international customer had a small linear accelerator dedicated to X-Ray inspection in urgent need of repair and LINAC refurbishment. They had serious consequences if they did not conduct their inspection by a certain date, and as a result, we repaired the LINAC inside of four weeks to meet the customer’s tight timeline. After removing, repairing and replacing the damaged Electron Gun and RF Window, we conducted an internal cleaning process to remove contamination, reassembled and processed the LINAC in our UHV bakeout station.

-

Start Date 12/20/20018

-

Customer: Treas Engineering

-

Product: LINAC Repair/Refurbishment

-

Altair Engineer: Ed Castillini

The Challenge & Solution

Overcoming the time constraints was the most challenging aspect of this project. Constant team communication and oversite to make sure the project consistently moved from one step to the next was necessary. It may sound odd, but knowing what *not* to do on this project was important. Familiarity with the industry and how a wide range of LINAC products are built, helped us avoid costly mistakes with customer-owned products like this; our experience enables customers to trust us with their equipment and repairs. Lastly, it was not straight forward. We also had to modify our cleaning process and methodology in real-time, because we were restricted from opening the LINAC target to give us better access.