Altair Technologies is committed to providing defect-free products and services that meet or exceed our customers’ expectations through the effectiveness and continual improvement of our Quality Management System.

The cornerstone of our ISO 9001:2015 certified quality system is a dedicated closed-loop corrective action that requires an ECO or training log in order to disposition/release a customer return or internal discrepant assembly. Because we are a turnkey, contract manufacturer, specializing in brazing, we require a high AQL at incoming and final inspection.

We take quality seriously and are proud of the work we do.

This, along with our supplier rating system and source control of raw materials, cleaning, plating, machining lubricants and virtually all supplies entering our facility, has achieved an ideal environment for producing strictly controlled high vacuum products.

We also have Lot Traceability, Serialization and virtually keep a permanent record of all Jobs. Altair conducts internal audits, Business System Review on a quarterly basis and in addition to the many external audits, undergoes a bi-annual ISO 9001 audit.

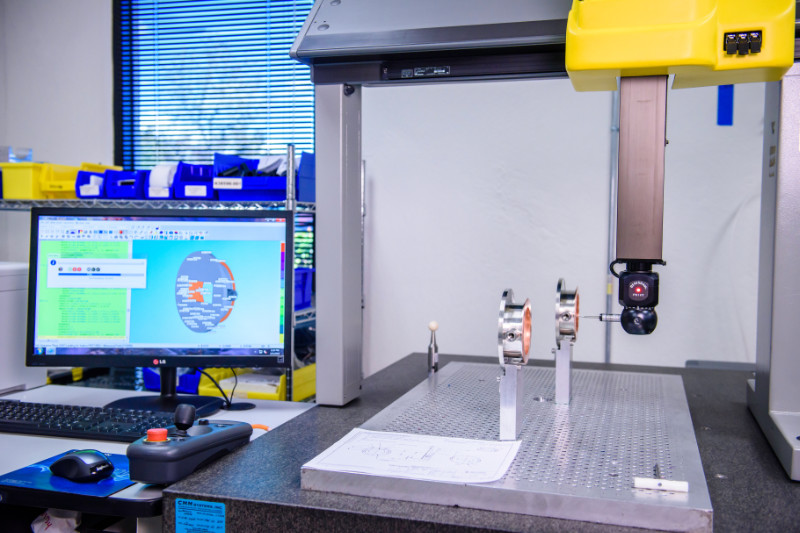

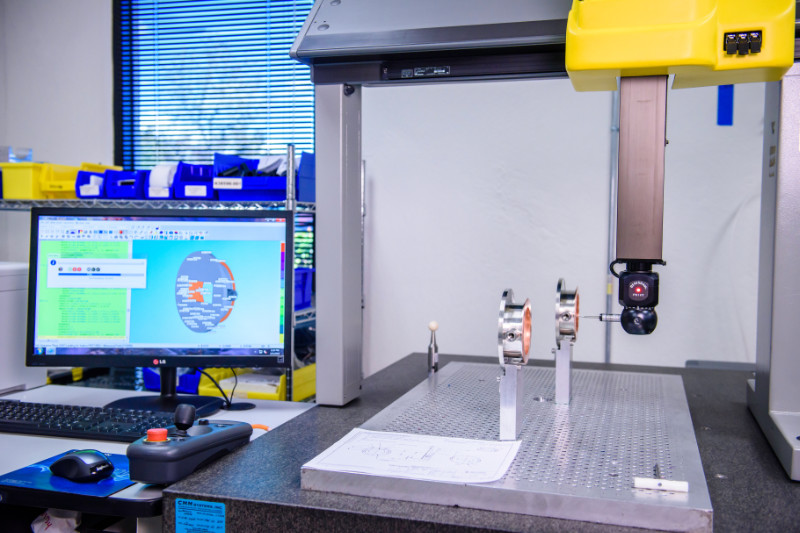

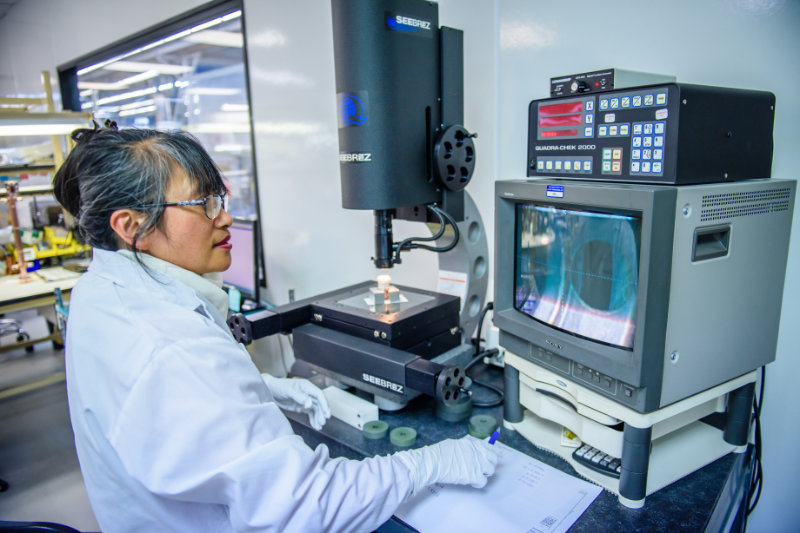

Quality Inspection Equipment & Facilities

Our Inspection Department uses automated and programmable CMM, precise X-Y-Z Optical, and manual tool inspection equipment. In addition to our quantitative measurements, we also perform a visual and sensory inspection to ensure surfaces meet the appearance standards customers keep returning to us for and that braze fillets (braze-joints) also conform to Altair’s and our customer’s requirements.

Delivering Customer Satisfaction

In today’s manufacturing landscape, quality and reliability are expected to be delivered hassle-free. Second, only to OTD (On-Time-Delivery) delivering consistent quality is the second most important deliverable to our customers in the semiconductor, medical, defense/aerospace, and research industries. We have been talking to our customers and conducting surveys to converge on what is most important to deliver to our customers and how that aligns with our business goals, constraints, and vision. As a result, our new 5 Principles of Manufacturing eloquently reveals we must sync our obligation to the customer with our business performance.

As OEMs and supply chains become more competitive and integrated, any breakdown in supplier performance is unacceptable. We understand and are committed to ensuring business performance is in sync with customer expectations. Our 5 Principles of Manufacturing summarize both Altair’s obligation to our customers and their expectations of business performance.