Vacuum Brazing

Vacuum brazing is well suited for exotic base metals such as Aluminum, Titanium, Zirconium, Niobium, Molybdenum, …

Brazing Metal – A Comprehensive Overview

We braze low vapor pressure metals like Copper, Stainless Steel, Kovar, Moly, Iron, Monel, Cupronickel, Nickel, …

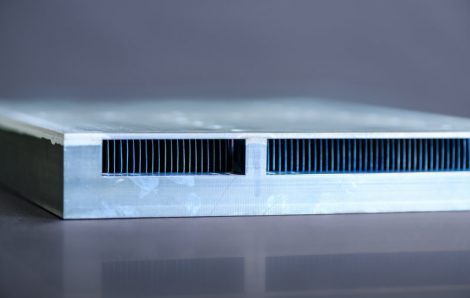

Brazing Aluminum

The best way to braze aluminum assemblies is in high vacuum furnaces that are specifically designed with the multi-zone …

Brazing Applications Above 1000 C

For brazing applications above over 1000° C, finding a braze alloy, or even base materials, that will withstand …

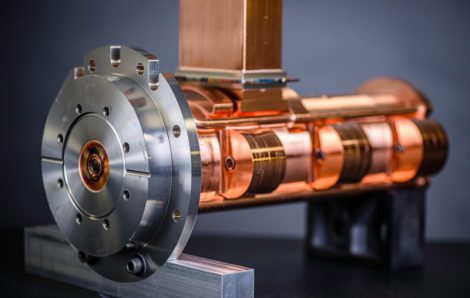

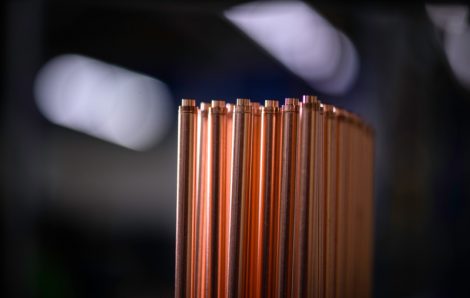

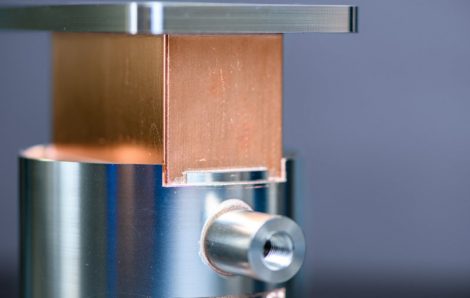

Furnace Brazing Copper in Hydrogen Gas

Furnace brazing copper in hydrogen gas is the best method to braze copper for accuracy, joint-strength and high-vacuum …

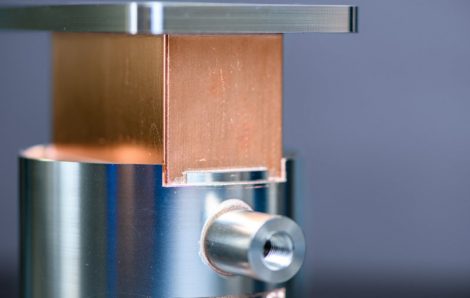

Diffusion Bonding

For a variety of applications, Diffusion Bonding joins dissimilar alloys (copper, titanium) with extreme force & …

Vacuum Aluminum Brazing 101

A high quality braze joint using vacuum aluminum brazing requires excellent material preperation, cleanliness and …

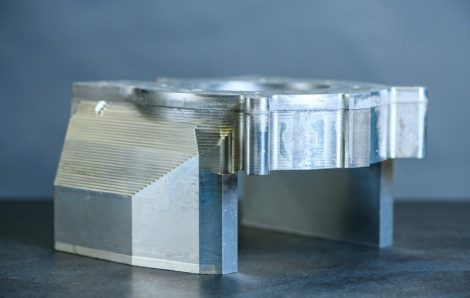

Advantages of Brazing Complex Geometries

When fabricating complex geometries, whether it’s by die casting, e-beam welding, or 5- axis machining, there can be …

Hydrogen Brazing – Wet & Dry

Furnace brazing in a hydrogen atmosphere that can be either wet or dry to reduce hydrocarbons or oxides while also …

Wetting Braze Flow and Filler Spreading

The term “wetting” is commonly used to describe the flow of braze alloy or braze filler across a surface when …

Vacuum Active Metal Brazing

Is when a metal like titanium is added to the braze alloy and chemically reacts with a ceramic surface, allowing the …

Brazing Ceramic To Metal

Applications for brazing ceramic to metal are most commonly found in microwave tube, semiconductor feedthru and laser …

Brazing Stainless Steel

Stainless is a low vapor pressure material best suited for wet or dry hydrogen brazing, depending on removal of oxides …

Brazing Ceramics

We routinely braze ceramics, particularly Alumina, but can also braze Zirconia, Quartz, Fused Silica, BeO, AlN, Si, SiC …

How To Read A Phase Diagram

Phase diagrams are a great tool for the Brazing Engineer; the binary phase diagram is an invaluable tool for why a …

Heat Treating & Clean Firing

We perform certain heat treating for a variety of materials and clean fire to remove unwanted vapor, oxides, …

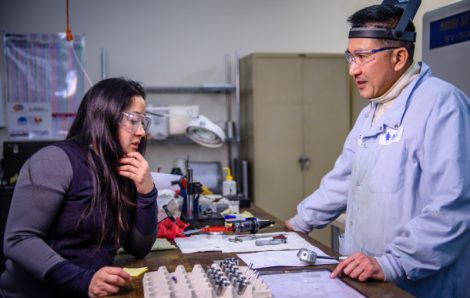

Chemical Cleaning

For almost two decades Altair Technologies’ in-house cleaning process has included a heated strong alkaline detergent …

Bakeout Services for UHV Applications

Bakeout Services at Altair Technologies provided two double vacuum bakeout stations capable of temperatures >600°C and …