Vacuum brazing is particularly well suited for joining complex geometries, precision assemblies and materials like aluminum or titanium, free of contamination. It is also sometimes favored over hydrogen atmospheres when processing very large parts because of the ability to purge occluded, close-fitting areas.

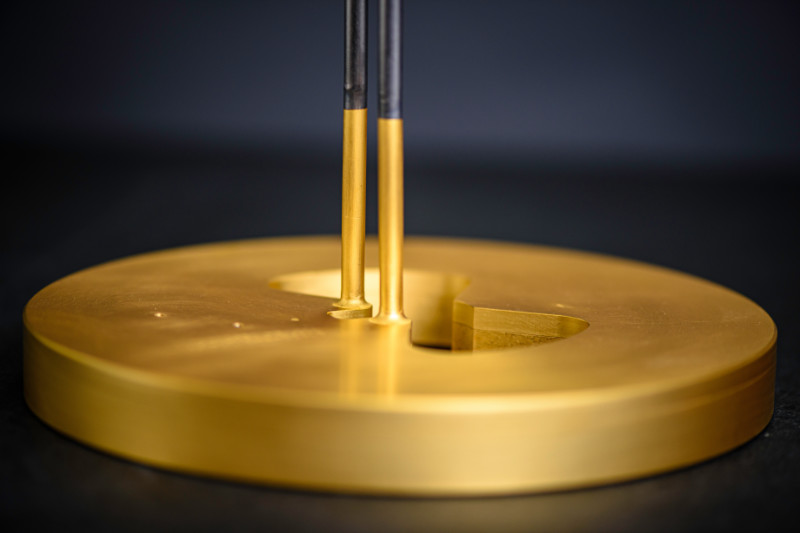

Vacuum furnace brazing deoxidizes the metals being joined and more importantly, eliminates undesirable reactions that would have occurred in hydrogen or other inert gases. The very low-pressure environment (Vacuum) promotes the wetting of surfaces when the heating systems achieve the melting-temperature of the braze alloy (filler or die-cut pre-form), facilitating flow into the joints via capillary action.

Lastly, the process is also used in the metallization of ceramic surfaces for joining ceramics to other metals by a process called Vacuum Active Metal Brazing.

Key Advantages & Benefits

Our vacuum brazing operations offer a clean process that removes nasty oxides and prevents undesirable reactions that yield high-quality braze-joints. For these reasons, vacuum brazing is highly sought after by the semiconductor, medical, aerospace industries because it can hold tight tolerances, is a clean process, and provides time and cost savings. Bright, clean and beautiful parts are produced without the need for post-processing whereas machining steps are required after welding. Furthermore, there is virtually no limit on wall thickness when brazing complex geometries or assemblies compared to welding processes.

Vacuum Brazing Applications

The most common applications leverage the thermal flow capabilities of aluminum and the deoxidizing nature of the process to join components that makeup heating and cooling assemblies, micro-channel heat exchangers, aircraft components, sensors, medical devices, structural components, and other thermal products. We are ITAR registered and ISO 9001 certified, hence we understand and serve the requirements of our defense and aerospace customers with ease.

| Parts and Equipment for Defense & Aerospace | Parts and Equipment for Medical |

| Heat sink and Electronics Cooling | Pressure vessels |

| Liquid Cold Plates | Electric Vehicle (EV) Components |

| Flat Tube Heat Exchangers | Aluminum Fin Heat Exchangers |

| Heat Pipes & Heater Tables | Electro-Static Chucks |

| Vacuum & Deposition Chambers | Instrumentation & Sensors |

| Hydraulic flow boxes | Thermodynamic Engines |

Vacuum Brazing Materials

With regards to materials and as explained above, we focus on the joining of reactive materials with the vacuum brazing process or materials where oxides are a priority to remove during the brazing process:

- Exotic base metals such as Aluminum, Titanium, Zirconium, Niobium, Molybdenum, and Tantalum

- Nickel and Iron-based alloys containing aluminum and/or titanium

- Refractory metals

- Reactive metals

- Ceramics & metal to ceramics

- Beryllium

Vacuum brazing aluminum is a hefty sector of our business and if you would like to learn more about our approach specifically to joining aluminum to itself and to other metals like Copper, Stainless Steel, and other refractory metals to aluminum while avoiding brittle intermetallic phases, we have provided specific design guidelines for excellent braze-joint quality and further details specific to how we join aluminum with the following two articles.

They are vacuum brazed when joining them to reactive metals due to the reactive metal’s oxidation or intrinsic contamination; titanium to aluminum for example. Refractory metals are the classification of metals that demonstrate very high melting temperatures, up to 3410° for Tungsten, which is more than double of Titanium. Refractory metals all share high corrosion and abrasion/wear resistance and excellent thermal and mechanical strength properties. Although there are twelve in this class of metals, only five are widely used: Tungsten, Molybdenum, Niobium, Tantalum, and Rhenium. [1]

Reactive metals are a group of metals that chemically react with exposure to air, water, acids, and mineral acids. With regards to material joining and brazing, these reactions can create surface oxides or present contamination during the brazing process which can cause a plethora of issues resulting in an unsuccessful braze-joint; vacuum brazing is the preferred process for this reason. For example, aluminum will react with air very quickly, producing undesirable surface oxides that require chemical cleaning to remove and then sealing in bags prior to the vacuum brazing process.

The Vacuum Brazing Process

Instead of using a protective and deoxidizing inert gas such as the common hydrogen process, it is fluxless and is performed at high temperatures and in an atmosphere with pressures typically in the x 10-5 – 10-6 range. This clean process also deoxidizes the metals being brazed, but more importantly eliminates reactions that would have occurred in hydrogen and helps to vaporize or remove high vapor pressure materials that are seen as contaminants.

Even vacuum firing can be used to remove hydrogen gas from materials like stainless steel, which were previously brazed in hydrogen. Many of the same braze alloys (filler or die-cut preforms) used with Hydrogen are also used with this process and we can join common materials like silver, copper and stainless steel.

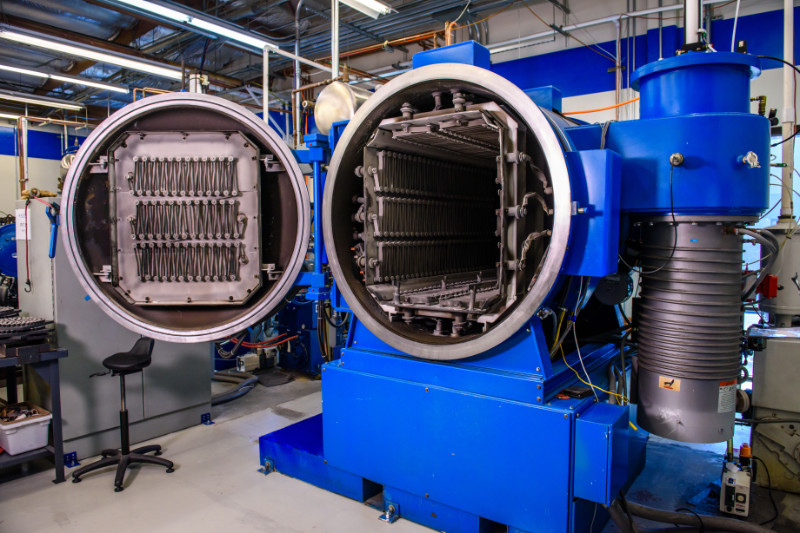

Vacuum Brazing Furnace Technology

Our high-efficiency vacuum furnaces are cold-walled retorts having either a graphite or Moly hot zone. Most vacuum furnace brazing technologies use ultra-clean cryopumps, while a few use very clean turbopumps to achieve consistent results. We have 14 furnaces of all sizes and our largest furnace has a 48” diameter hot zone.

- Furnace Vacuum Range: 10-5 & 10-6

- 48” x 28” x 28” Hot Zone

- Temperature Profile Recording

In addition to several proprietary processes and designs developed at Altair as Trade Secrets, we currently have a patent-pending associated with an innovative solution for the vacuum brazing of aluminum.

Contact one of our specialists today for a quick feasibility study of your project.

[1] A full background on the definition of refractory metals