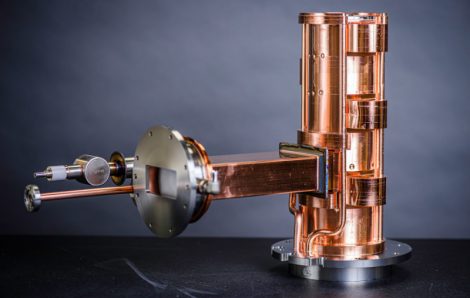

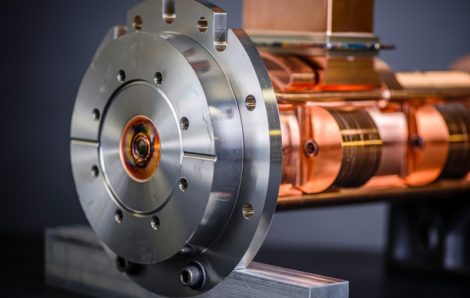

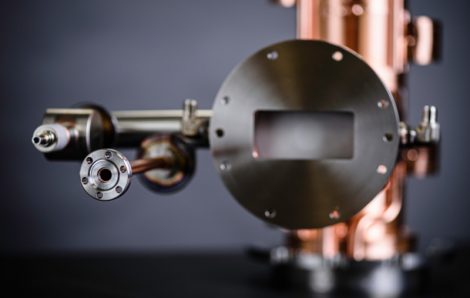

Role Of The Linear Accelerator (LINAC) In Cancer Radiation Therapy

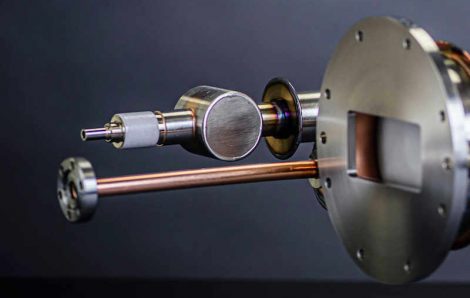

The RT machine uses the linear accelerator (LINAC) as the source of the ionizing radiations which can be high energy …

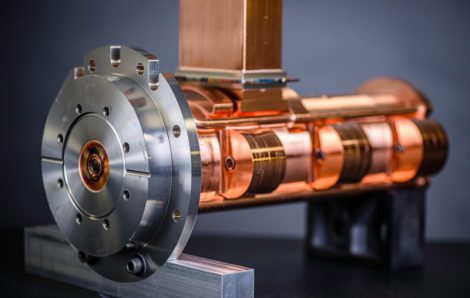

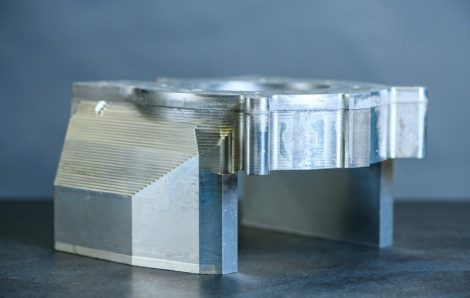

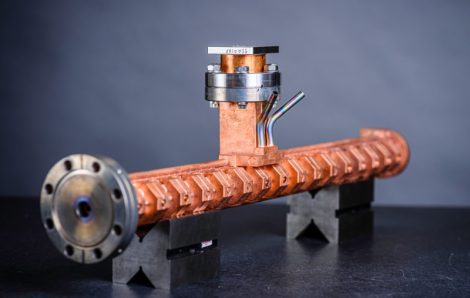

Manufacturing Techniques Of A Linear Accelerator (LINAC)

Manufacturing linear accelerators require materials and fabrication methods to be compatible with ultra-high vacuum, …

Brazing Ceramic To Metal

Applications for brazing ceramic to metal are most commonly found in microwave tube, semiconductor feedthru and laser …

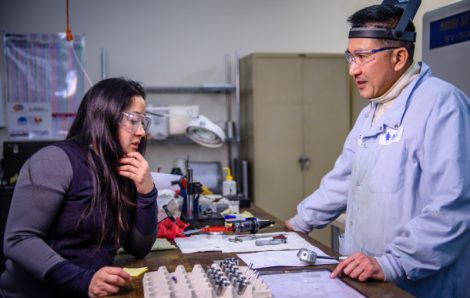

Engineering Services

We are an engineering-savvy brazer offering collaborative services that cover metallurgy and braze-joint designs to …

Vacuum Brazing

Vacuum brazing is well suited for exotic base metals such as Aluminum, Titanium, Zirconium, Niobium, Molybdenum, …

Brazing Metal – A Comprehensive Overview

We braze low vapor pressure metals like Copper, Stainless Steel, Kovar, Moly, Iron, Monel, Cupronickel, Nickel, …

IMG Expands Capabilities with Acquisition of Altair Technologies

IMG has announced the acquisition of Altair Technologies Inc. and the recapitalization of the Company together with …

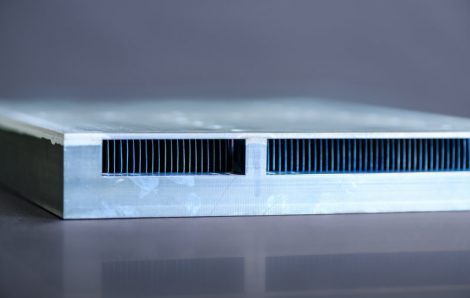

Brazing Aluminum

The best way to braze aluminum assemblies is in high vacuum furnaces that are specifically designed with the multi-zone …

Brazing Applications Above 1000 C

For brazing applications above over 1000° C, finding a braze alloy, or even base materials, that will withstand …

Atmosphere Brazing

Our furnace brazing services offer the Atmosphere Brazing process that includes inert gases like Nitrogen, Argon, …

Quality & Inspection

We are ISO 9001:2015 certified and provide defect-free products and services that exceed expectations via the …

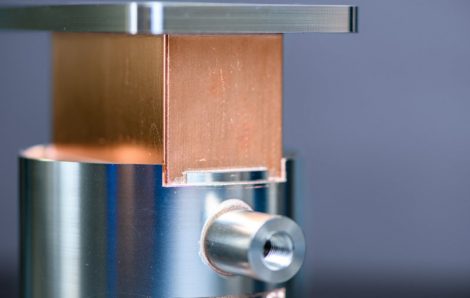

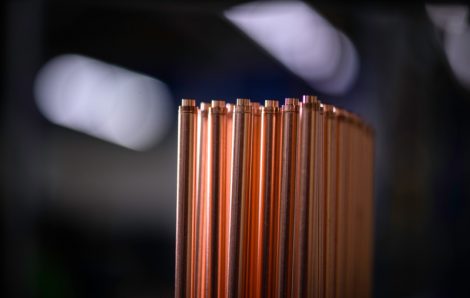

Furnace Brazing Copper in Hydrogen Gas

Furnace brazing copper in hydrogen gas is the best method to braze copper for accuracy, joint-strength and high-vacuum …

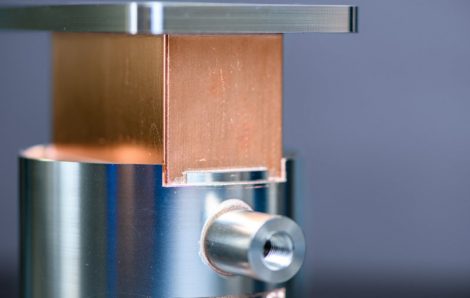

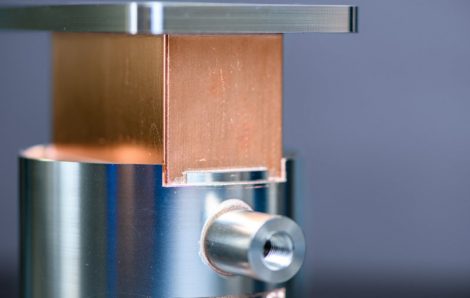

Diffusion Bonding

For a variety of applications, Diffusion Bonding joins dissimilar alloys (copper, titanium) with extreme force & …

Engineering & Design

The Altair team is unmatched in the design, development, and manufacturing of products for the medical, security, …

Vacuum Aluminum Brazing 101

A high quality braze joint using vacuum aluminum brazing requires excellent material preperation, cleanliness and …

Advantages of Brazing Complex Geometries

When fabricating complex geometries, whether it’s by die casting, e-beam welding, or 5- axis machining, there can be …

Altair Technologies Inc. launches an all-new website, ARG and their 5 Principles of Manufacturing

Altair USA launches an all-new website, ARG and 5 Principles of Manufacturing to better serve the Semiconductor, …

Hydrogen Brazing – Wet & Dry

Furnace brazing in a hydrogen atmosphere that can be either wet or dry to reduce hydrocarbons or oxides while also …

Wetting Braze Flow and Filler Spreading

The term “wetting” is commonly used to describe the flow of braze alloy or braze filler across a surface when …

Vacuum Active Metal Brazing

Is when a metal like titanium is added to the braze alloy and chemically reacts with a ceramic surface, allowing the …

Recent Advances in X-ray Cargo Inspection Part II

Recent X-Ray Cargo Inspection use X-ray computed tomography, dual energy X-ray systems, and combining them into the …

DRC Conflict-Free Sourcing

Altair Technologies, Inc. takes very seriously the worldwide concerns that metals mined in the conflict areas of the …

Linear Thermal Expansion Calculation – CTE

A sample calculation using CTE (Coefficient of Thermal Expansion) for determining the nominal dimensions when …

Brazing Stainless Steel

Stainless is a low vapor pressure material best suited for wet or dry hydrogen brazing, depending on removal of oxides …

Brazing Ceramics

We routinely braze ceramics, particularly Alumina, but can also braze Zirconia, Quartz, Fused Silica, BeO, AlN, Si, SiC …

Role of the Linear Accelerator (LINAC) in Security and Cargo Inspection – Part I

Security & Cargo Inspection stations in many ports around the world rely on X-ray scanners to inspect for nuclear …

Thermal Expansion When Brazing

For most materials (copper, stainless,etc.) expansion varies from four to twenty thousandths of an inch of growth per …

How To Read A Phase Diagram

Phase diagrams are a great tool for the Brazing Engineer; the binary phase diagram is an invaluable tool for why a …

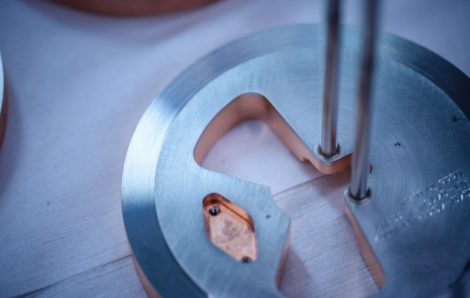

High Voltage Processing & Cathode Emission

Electron Guns, Collectors, Insulated Targets and other isolated high voltage assemblies can be hi-potted to ensure …

Heat Treating & Clean Firing

We perform certain heat treating for a variety of materials and clean fire to remove unwanted vapor, oxides, …

Chemical Cleaning

For almost two decades Altair Technologies’ in-house cleaning process has included a heated strong alkaline detergent …

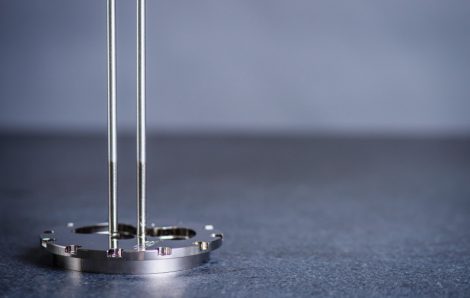

8-Liter Ion-Pump Design

The 8-liter ion pump is a staple in the high vacuum community and with the increased demand for longer-lived vacuum …

Leak Detection

Altair has several manufacturing processes to support our turnkey services and vacuum product lines which include …

RF Linear Accelerators For Medical And Industrial Applications

A friend of Altair Technologies, Dr. Samy Hanna, has authored a new textbook, RF Linear Accelerators for Medical and …

Bakeout Services for UHV Applications

Bakeout Services at Altair Technologies provided two double vacuum bakeout stations capable of temperatures >600°C and …

3D CAD Modeling To Optimize Braze Design

Altair engineering’s knowledge and expertise with CAD parametric modeling can provide the service you need for …

New X-ray Target Surface Finish

We developed an automated process that uses no foreign matter or polishing compounds, yet achieves the desired surface …

Turnkey Processes & Quality Control

We continually strive for process control, improvement and the relative expertise we need to meet or exceed our …

High Voltage RF Feed Throughs

Altair produces a number of high-voltage and RF Feed Throughs that were either custom designed or built to our …

Altair Technologies Ships X-Band Mobetron Accelerator

Altair Technologies, a leader in designing and manufacturing Linear Accelerators, is excited to ship a turnkey X-Band …